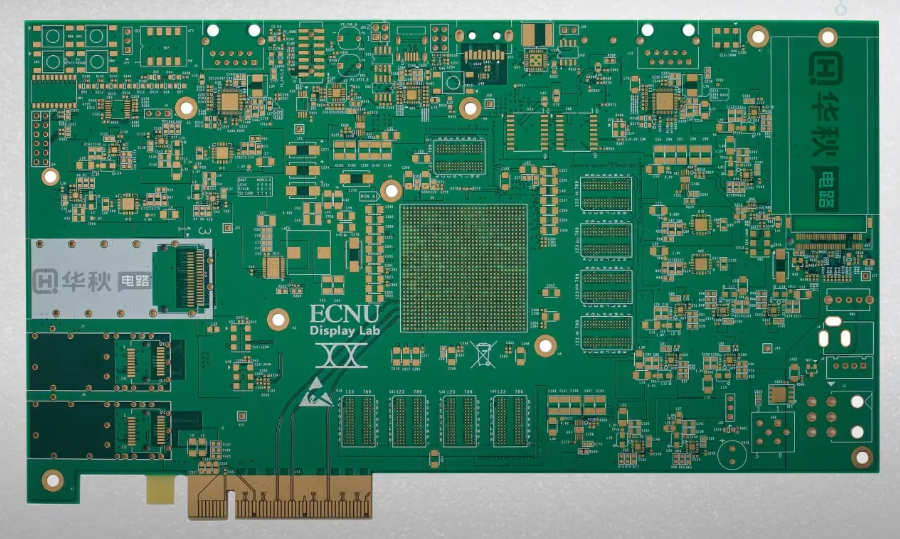

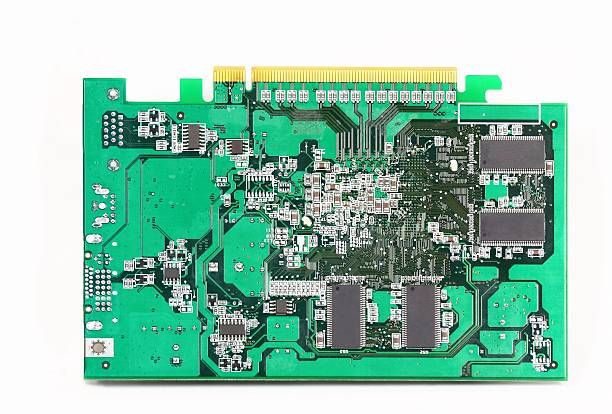

The copper clad laminates( CCLs) are highly vital to the performance and quality of printed circuit boards (PCBs). This article will help beginners and those who have been in PCB design but are still ignorant about copper clad laminates. In the following article we will explain what copper clad laminates are and how they are produced, what types of CCL there are and their characteristics.

What are Copper Clad Laminates?

Copper clad laminates are a kind of laminate that combines a supporting dielectric material or dielectric breakdown voltage such as fiberglass, or other insulating materials with a layer or more of copper that is then electroplated on one side or both. Such these laminates are used as the base for the PCBs along with the pathway of electric conductivity.

Types of Copper Clad Laminates

It is important to understand that copper clad laminates (CCLs) are of different types, each type of CCL being suitable for different applications in the electronics industry. The following types are understood in order to select the right reinforcing material for the PCB design. Here’s a closer look at the different types of copper clad laminates:

FR-4 (Flame Retardant 4)

- The base of the most commonly used Copper Clad Laminate.

- They are manufactured using glass fiber cloth that is woven into the epoxy resin ccl.

- A material whose physical properties include good electrical insulation characteristics and mechanical strength, mechanical rigidity as well as high fire resistance.

CEM-1 (Composite Epoxy Material)

- Paper core covered by epoxy resin.

- Less expensive than FR-4.

- Suitable for single-sided PCBs.

CEM-3

- A composite fibre-glass known for its good manufacturing properties which are similar to FR-4 but contains a woven glass fabric core.

- Provides high quality electrical performance in compare to CEM-1.

- It can be applied in double sided printed circuits.

Polyimide

- Has high heat resistance and is flexible.

- Ideal for high-temperature applications.

- Tagged for aerospace and military applications.

Teflon (PTFE)

- characterized by high class dielectrics and low signal attenuations.

- Insulation resistance: suitable for high frequency system like RF and microwave circuits.

What makes the Best Copper Clad Laminate?

The best copper clad laminate (CCL) combines several key qualities to ensure optimal performance, reliability, and cost-effectiveness for PCBs:

- High Electrical Insulation: It shows minimum electrical passing and maximum dielectric strength.

- Thermal Stability: It can sustain extreme heat temperatures and retain its functionality.

- Mechanical Strength: Does not react violently physically to physical stress and deformation during manufacture and operation.

- Low Signal Loss: The choice of a proper diplexer is especially important for high-frequency signals and minimization of the signal degradation.

- Chemical Resistance: Chemicals used during the processes of making of PCBS have no effect on this substance.

- Flame Retardancy: It also helps in alleviating risk and safety concerns by reducing the risk of fire.

- Cost-Effectiveness: Recognises performance and affordability of the product in different needs.

- Flexibility: Excel for use in mechanical applications that require bending and flexing such as flexible circuitry.

Manufacturing Process of Copper Clad Laminate ccl

The production of copper clad laminate for the manufacture of PCBs requires several steps with some of the key stages summarized below. Here’s a concise overview of the process:

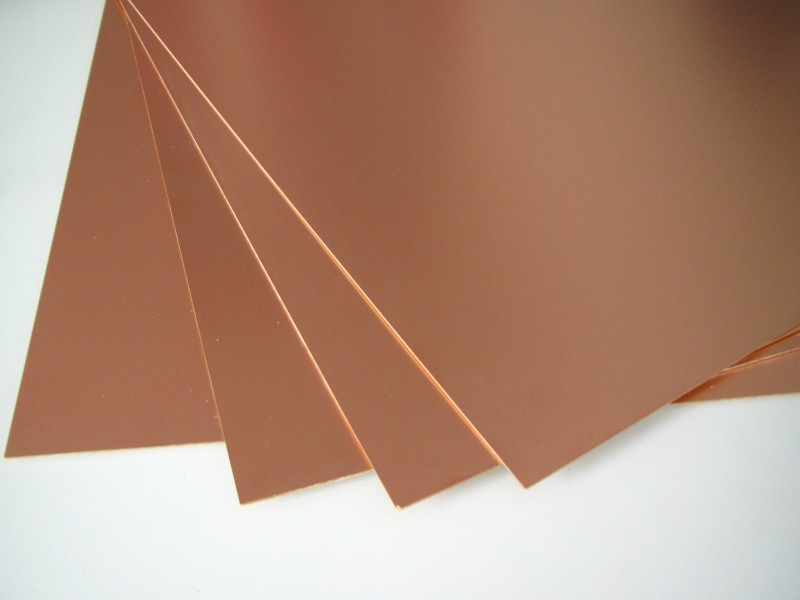

- Preparation of Base Material

Surface conducting layer is prepared: a surface of the substrate material which is usually made of fiberglass or other insulating materials. This will involve cutting the material to the desired length and clean of all impurities.

- Resin Impregnation

The substrate is coated with a highly adhesive brominated epoxy resin to achieve the required properties. The initial version of this material is prepreg – a kind of fiberglass coated with resin.

- Lamination

Next, prepreg layers are laminated to standard copper foil side sheets on one or both sides to form a multilayer structure. This stack is then put in the above lamination press.

High heat and pressure causes the resin to harden and glue together into a laminated or bonded sheet with the copper foil stuck firmly to the substrate.

- Curing

The cured laminated sheets are preheated in an oven to complete up the polymerization of the resin. This step helps in firming up the mechanical strength and stability of the laminate.

- Cooling and Trimming

The laminated sheets are then allowed to cure when they are frozen and allow to cool. They are then cut to the required sizes to ensure that the edges come out in an exact and uniform manner.

- Surface Treatment

The copper plate surfaces are also decorated so as to promote the attachment for subsequent treatments. This may include chemical cleaning, microoperation, or a printed protective layer or insulating layer to help prevent corrosion.

- Quality Inspection

Thus, the finished products are subjected to quality control tests to determine whether the laminates meet the required industrial specifications. This includes looking for thickness uniformity, surface resistance blemishes and the copper foil outside of the panel at the ends being bonded correctly.

- Cutting and Packaging

The laminate compounds are cut into the right dimensions depending on the orders made by customers. They are then properly packaged so that they do not get smashed during storage or transportation.

How Copper Clad Laminates are Classified?

Copper clad laminates (CCLs) are classified based on several key factors:

- Base Material

- FR-4: Epoxy and fiberglass reinforced composite prepreg materials.

- CEM-1 and CEM-3: Layered materials of organic matrices with the use of paper or glass fabric components.

- Polyimide: THERMOCURE 2741 Thermosetting polymer for high-temperature application.

- PTFE (Teflon): Appropriate for high frequency usage.

- Paper Phenolic: Paper and phenolic motifs with low cost fibrous constrained material.

- Copper Foil Thickness:

- Standard thicknesses include 1 oz/ft² , 2 oz/ft² …and so on ; these influence the conductor’s electrical performance as well the current carrying capability.

- Number of Copper Sides:

- Single-Sided: The RCF shall be one side copper foils.

- Double-Sided: Copper two-foil.

- Flexibility:

- Rigid: For use in structures that require some stiffness.

- Flexible: When it comes to the applications involving bending and flexing.

- Flame Retardancy:

- FR (Flame Retardant): Substantial plastics that are hard for burning such as FR-4.

- Non-FR: Materials with no flame retardant feature.

- Thermal Conductivity:

- Regular laminates for applications in normal conditions.

- Second generation interface for thermal management in power electronics such as power and ground planes.

Properties of Copper Clad Laminates

These are the properties of Flexible Copper clad laminate:

- Electrical Insulation:

- It is electrically non conductive and do not allow the passage of electric current it has high dielectric strength that reduces leakage.

- Excellent insulating properties.

- Mechanical Strength:

- Mechanically strong and can resist mechanical disintegration.

- Tensile and flexural strengths – high, high.

- Thermal Stability

- Processability at higher temperatures without losing integrity.

- High heat and thermal shock resistance.

- Flame Retardancy:

- It retains high resistance in preventing fire outbreak therefore making it ideal for the safety aspect.

- Found in mediums as FR-4.

- Chemical Resistance:

- They are all resistant to chemicals used in manufacturing of printed circuit boards.

- High resistant to solvents, acids and alkalis.

- Surface Smoothness:

- Flat copper to be used for accurate etching of circuits.

- Description: A very useful component that is essential for high precision PCB designs.

- Dimensional Stability:

- Keeps form and remains the same size irrespective of environmental conditions.

- Low moisture absorption.

- Signal Performance:

- Refractive index is very large; this means that it does not allow a high level of signal loss for high-frequency operations.

- Stable dielectric properties.

Applications of Copper Clad Laminates

Copper clad laminates are essential to the printed circuit board manufacturing industry because they give shape and serve as the connection between the components of a PCB board. Here’s an overview of the various applications of CCLs:

1. Consumer Electronics

- Examples: Cell phones, tablets, desktops, computer monitors, and gaming consoles.

- Requirements: Rugged performance, compact size, low cost.

- CCL Types: FR-4 mostly because of its fair balance in all parameters and cost effectiveness.

2. Automotive Electronics

- Examples: ECU or BCM, GNB, ADAS, MVB, and lighting system.

- Requirements: Will be resilient to high temperatures; will last long in use; will be resistant to harsh environments.

- CCL Types: FR-4 for high frequencies and MCPCB for heat dissipation.

3. Telecommunications

- Examples: Communicator router , comm switch , base station , satcom devices.

- Requirements: High speed, low attenuation, and low drop out.

- CCL Types: High-frequency specs: polytetrafluoroethylene (PTFE)-based, general specs: FR-4.

4. Industrial Equipment

- Examples: Control panels, probes, drive devices, power supply.

- Requirements: There is very high mechanical strength, thermal stability and also being reliable even under continuous usage.

- CCL Types: Where as FR-4, CEM-3 for cost.

5. Medical Devices

- Examples: Medical devices: Marketers try positioning diagnostic equipment, monitoring systems, and wearable health devices.

- Requirements: Reliability, compactness and medically compatible properties.

- CCL Types: Flex circuit materials: polyamide, general circuit materials: FR-4.

6. Aerospace and Defense

- Examples: Main devices such as avionics, radar, communicating equipment and navigation systems.

- Requirements: The high thermal stability, mechanical strength, and reliability under high-temperature service conditions are just a few of the properties that make the selection a good choice.

- CCL Types: One material for high temperature application, the other for high frequency applications.

7. LED Lighting

- Examples: Clear LED bulbs, led strips and backlight unit.

- Requirements: The design ensures heat dissipation, long term reliability and cost effective.

- CCL Types: The MCPCB application to help dissipate heat produced by the LEDs.

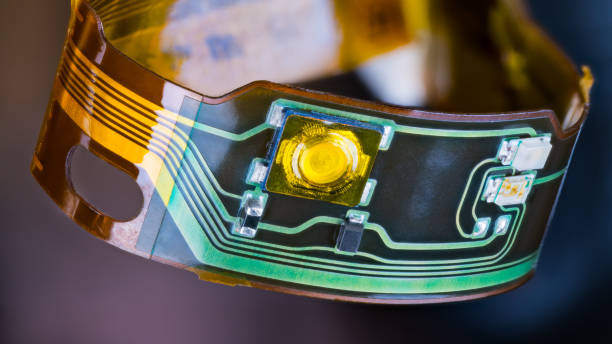

8. Flexible Electronics

- Examples: Wrist watches or patches, bends and rolls, phones that fold over and bend, the augmented senses.

- Requirements: Flextural properties: High flexibility and toughness in bending.

- CCL Types: Structurally bendable rigid-flex printed circuit boards fabricated from polyimide or polyester resin ccl film.

9. Power Electronics

- Examples: Inverters, power conditioners, power sources, speed controllers.

- Requirements: Thermal conductivity, wide insulation, high mechanical strength.

- CCL Types: high quality MCPCB for various application and FR-4 for general applications.

Conclusion

Copper clad laminate can stated as a parent of PCB because of its importance as fundamental basis for electronic circuits that have become a front of contemporary life. Once aware of the various types of CCLs such as phenol formaldehyde resin or phenolic resin ccl. Once aware of the various types of CCLs , the materials that make up these CCLs and their properties and applications, you can consider what type of CCL would best suit a given PCB design project. Whatever the frequency range, the coefficient of thermal expansion requirement or cost is, the right copper clad laminate is used.

Also some more articles on more specific PCB materials and technologies will follow soon as we taking a walk through the electronics world of today’s products.