Empowering Innovation Through Precision PCB Solutions

We deliver superior PCB products and services through the utilization of cutting-edge technology and modern manufacturing techniques, offering solutions tailored to meet our clients' needs.

With state-of-the-art facilities and a dedicated team, we guarantee superior products that meet and exceed your expectations.

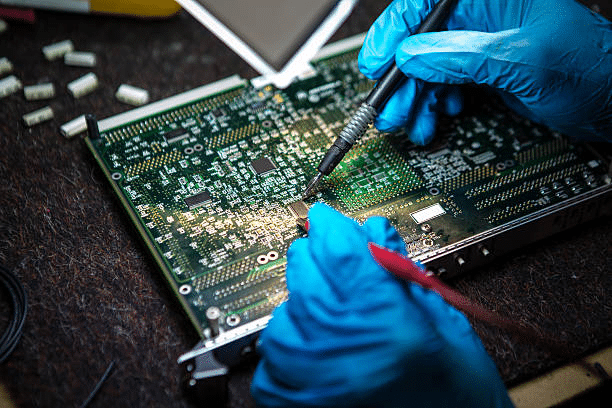

Rigorous Testing

100% Electrical Test

Online Support 24/7

Support Online 24 hours

Quick Turnaround Time

Fastest 3 days

Comprehensive Support

Comprehensive Turnkey Solutions

PCB Services We Offer

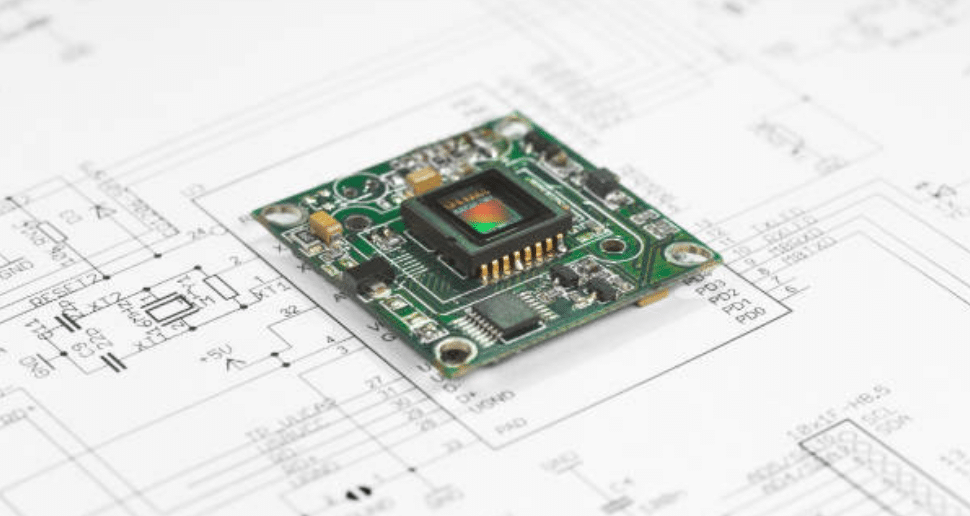

PCB Design & Layout Services

Offering comprehensive PCB design services from concept to production, including schematic capture, PCB layout, and design verification.

Rapid Prototyping

Providing fast PCB prototyping services for clients who need to quickly validate their designs, ensuring quality while significantly reducing delivery times.

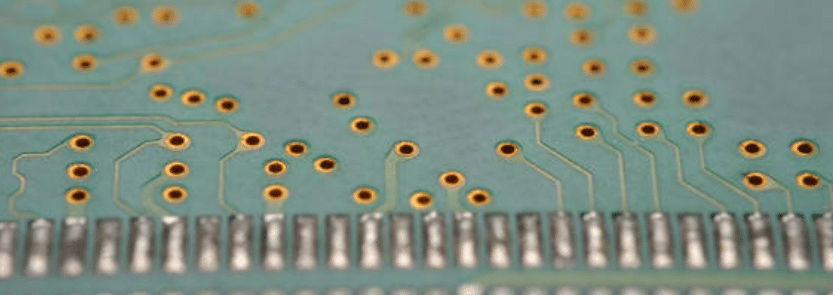

Multi-layer PCB Manufacturing

Capable of producing up to 40-layer high-density interconnect (HDI) PCBs, suitable for advanced electronic devices.

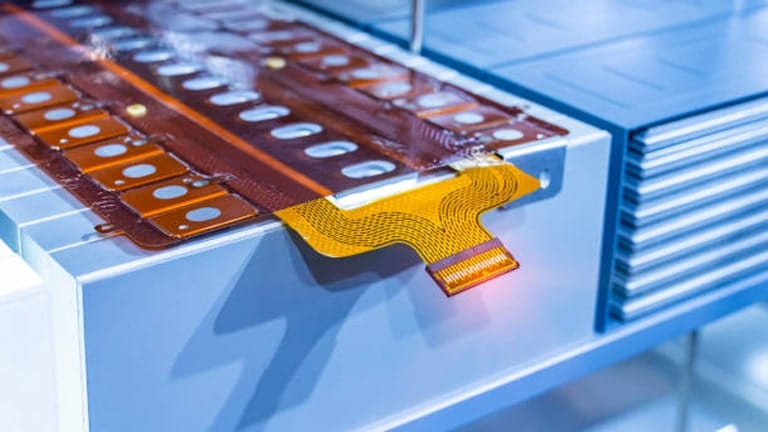

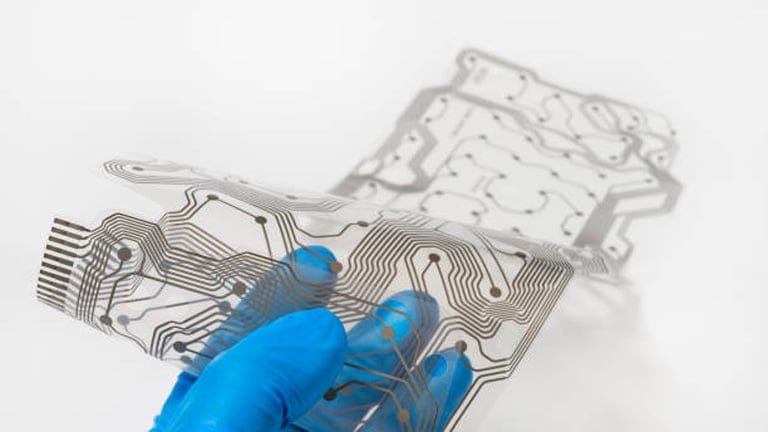

Flex and Rigid-Flex PCB Manufacturing

Offering manufacturing services for flexible and rigid-flex PCBs, ideal for applications requiring specific mechanical bending and folding.

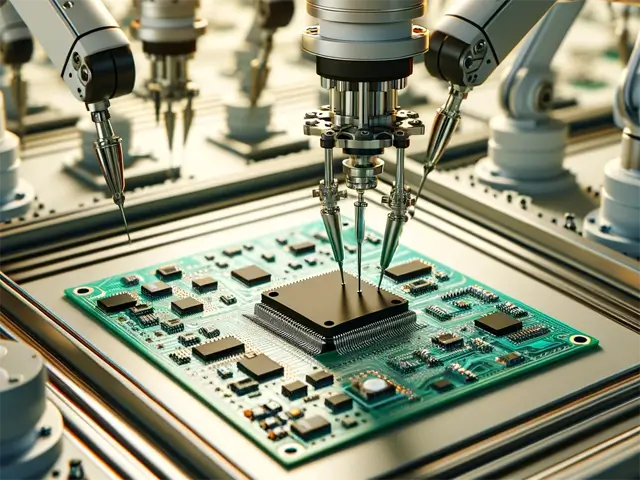

Component Sourcing and Assembly

Delivering one-stop PCB assembly services, including component sourcing, SMT placement, and DIP insertion.

Testing and Quality Assurance

Each PCB undergoes rigorous electrical testing and quality control processes to ensure high performance and reliability before delivery.

Special Materials and Processes

Producing PCBs with special materials and processes upon request, such as high-frequency PCBs, thick copper PCBs, and aluminum-based PCBs.

Post-Processing Services

Includes a variety of PCB post-processing options like metallized holes, silkscreen, and surface treatments.

- Versatile Customization: 1-40 layer PCBs in various materials including FR4, aluminum, and flex-rigid.

- DFM Checks: Ensures manufacturability and quality with thorough design checks.

- Fast Turnaround: 24-hour manufacturing with no minimum order requirement.

- Certified Excellence: Compliant with ISO 14001, ISO 9001, ISO 13485, RoHS, UL, IPC standards.

- Advanced Technology: Cutting-edge capabilities for HDI and complex designs.

- Precision Manufacturing: Focus on impedance control for reliable signal performance.

PCB Assembly

- Scale Adaptability: Expertise in both small and large-scale SMT & PTH PCB assembly.

- Cost-Effective Component Sourcing: Customized component procurement with cost-saving options.

- Rigorous Quality Checks: Advanced inspection with 3D SPI, AOI, FAI, X-Ray equipment.

- Certification Compliant: Adheres to ISO 14001, ISO 9001, ISO 13485, RoHS, UL, IPC standards.

- Customized Assembly: Tailored PCB assembly to meet specific customer needs.

- Efficient Processes: Rapid turnaround for streamlined assembly operations.

Why Choose CAMTECH PCB?

We are proud to say that we always provide high-quality PCBs/PCBAs, and we have been on the way to improving quality – we believe that high quality is the most important factor for customers to choose/trust Camtech PCB.

Condidentiality Agreement And Ensure That Your Personal Information Is Only Used

Flexibility

We respond quickly to your changing needs. Our working hours and styles are flexible to meet your variable needs. For us, your requirements are the guidelines and rules we should follow.

Save Your time

We can save you time from one phase of a project to another. We can handle all things in a simplified process, and all services are under one roof

Cost reduction

This is the most important benefit of your long-term relationship with us.After understanding your specific needs, we will quickly develop customized integrated solutions to meet your spending and cost reduction goals.

Information Security Protection

We can sign a confidentiality agreement and ensure that your personal information is only used for orders.

Countries Worldwide

Camtech PCB products are globally recognized, selling USA, South America, EU, Middle East, and Asia.

Different Industries Use Our Products

Camtech PCB has proudly served thousands of satisfied customers, showcasing a legacy of trust and excellence in service.

OUR PCB ASSEMBLY AND MANUFACTURING PROCESS

Establish a systematic qualty management system. We can coninuously optimize and promote traceability management from standardizing operation,maintaining equipment, managing change & deviation, and controlling key items to fulfil product quality requirements.

Diverse Industry Applications of Our Products

Our products are utilized in a wide range of industries, from telecommunications and consumer electronics to automotive and military applications, demonstrating versatility and reliability.

Automotive

CONSUMER ELECTRONICS

Medical Systems

Led lighting

Marine

New Energy

Artificial Intelligence

Laser Measurement

PRODUCTS WE MANUFACTURE

Our products are widely applied in security & defense, industrial control, communication, medical instruments, computing, 5G, automotive electronics etc.

State-of-the-Art Equipment: The Backbone of Our Excellence

At Camtech PCB Co., Ltd., we are equipped with the latest in PCB and PCBA manufacturing technology. Our state-of-the-art machinery, including advanced SMT lines, automated assembly systems, and precision testing equipment, ensures top-tier product quality. This technological prowess allows us to meet complex design requirements with efficiency and precision, setting new industry standards in innovation and reliability.

Latest Blog Posts

Step-by-Step: Integrating Via-in-Pad Structures into Your PCB Assembly Process

Implementing Via-in-Pad structures into your PCB assembly requires a step-by-step process that guarantees signals’ dependability and circuit performance. It begins

The Ultimate Guide to Optimizing Your PCB Layout for Efficiency

Printed Circuit Boards (PCBs) are fundamental components in various electronic devices, constructed using different materials to optimize performance and durability.

PCB Board Material Breakdown: Understanding Properties and Applications

The document “PCB Board Material Breakdown: The writing titled “Understanding Properties and Applications” gives information concerning the materials used in