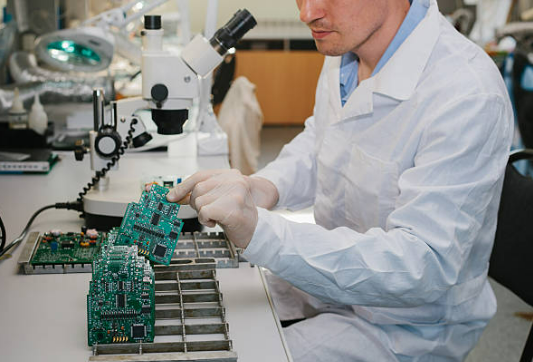

Discover the art of simplifying the PCB assembly with our complete tutorial. Move your knowledge of the basics to advanced procedures. This way, you will know how to assemble with ease for better outcomes. The depth of consideration involved the supply chain, manufacturer settings, quality control processes, and optimization techniques. Whether you are an inexperienced pro or have already acquired appropriate skills, this guide provides you with learning materials and techniques that help you streamline your workflow without compromising the results. Become an expert and tackle the overwhelming array of electronic assembly and obstacles with calmness and ease.

What is a Turnkey PCB?

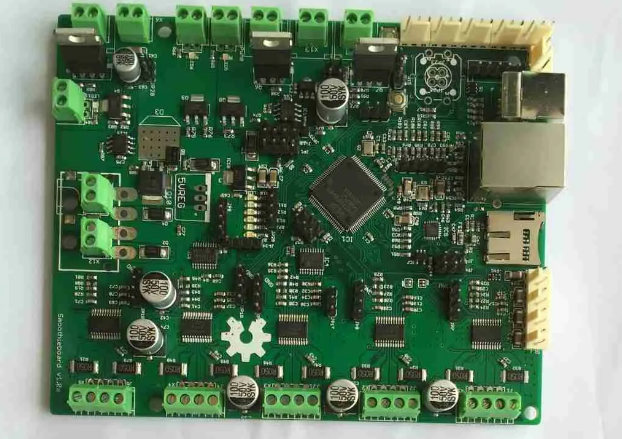

Turnkey PCB is a PCB solution, which means that the manufacturer takes care of every single step of the process, starting with the component sourcing up to the fabrication and assembly. In effect, you just tell the manufacturer your needs according to the specification, and they will do the rest, giving you a fully tested and ready-to-use PCBA. Hence, the above method can lead to a sleek customer experience where they do not have to coordinate with the vendors themselves and instead can receive a product that meets their expectations. The services offered by turnkey PCB include the procurement of electronic assembly components themselves, Printed Circuit Board (PCB) fabrication, assembly, testing, and sometimes the final put-together PCB assembly.

Types of Turnkey PCB Assembly Services

The types of turnkey PCB services range from those in which services as well as the client’s involvement are limited to a single vendor to those that are comprehensive and involve the client to the maximum level.

Full-turnkey PCB Assembly

This category will cater to PCB one-stop-shopping process, where the manufacturer does all the production requirements, starting from design support to parts procurement to final assembly and testing. The customer just has to supply the different design files along with a set of specifications and then the manufacturer handles the entire sourcing process, including obtaining components, fabricating PCBs, assembly, testing and sometimes even shipping the final product.

Partial Turnkey PCB Assembly

This category of vertical manufacturing may include the client who produces some parts of the production process and the manufacturer who outsources certain parts to PCB manufacture to him. For instance, a customer might partially assemble the PCBs or provide some of the components while the manufacturer completes the assembly phase.

Prototype Turnkey PCB Assembly

Turnkey prototype services are customized with clients with small quantities of PCBs for R&D and production. Such services indeed concentrate on fast delivery and struggle to align with client’s intended design changes. Owing to their support in design optimization, component sourcing, fabrication, assembly, and testing of prototype PCBs, the manufacturers offer the highest quality in their services.

Production Turnkey PCB Assembly

Production Turnkey Services is focused on those clients that have large orders of PCBs for rapid mass production. These services are in line with the trend of efficiency, cost-saving and scalability. The manufacturer has to handle the entire production process, namely component procurement, high-volume part production post-assembly, and testing.

Quick Turn PCB Assembly (QTA)

Quick turn PCB assembly services mainly act on predecessors, which include rapid prototyping. They are convenient for people with short-term project timelines and minimum quantity requirements and/or those who need quick production of small amounts of PCBs in a short span of time. Time-lapses manufacturing systems mostly seek to speed up the production steps but with a high level of precision.

With a range of different turnkey solutions and PCB services, manufacturers are able to provide a supply for each client’s varying needs and preferences. Manufacturers then give the clients a variety of options to choose from, which are most suited for their project requirements and setbacks.

Turnkey PCB Fabrication & Assembly Capabilities

Turnkey PCB fabrication and assembly facilities coverage is a comprehensive service where a manufacturer supplies all required electronic manufacturing services that range from the production of ready-to-use printed circuit boards to its customers. Here are some key aspects of turnkey PCB fabrication and assembly capabilities:

- Design Support: Experienced engineers and design teams can mentor the engineering team in improving circuit designs passing through the manufacturing phase and the cost effectiveness parameter.

- Component Sourcing: Acquisition of a reliable and official supply of components, confirming lead times, quality, and consistency with the design.

- PCB Fabrication: Implementation of sophisticated methods and innovative machinery for the fabrication of precise, high-standard PCBs.

- Assembly Services: SMT (surface mount technology) and THA (towel hardware assembly) are necessary for the accurate and efficient placement of components on PCBs.

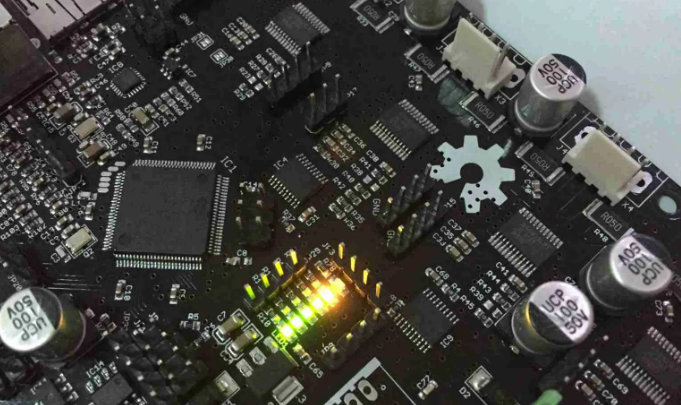

- Testing and Inspection: The implementation of strict design and fabrication testing protocols for each assembled PCB as well as quality control measures to ensure the functioning and reliability of the assembled PCB.

- Quick Turnaround Time: Scale production processes for meeting delivery deadlines and rapid prototyping of products and designs.

- Customization Options: Flexibility to accommodate PCB sizes and shapes of different categories, including multilayer boards and any other complicated materials option, can be done.

- Documentation and Support: Extensive monitoring and record-keeping of the production steps, coupled with a technical support service for our clients.

- Value-Added Services: An additional service of conformal coating, potting, and final product assembly may be given in respect of customer needs.

- Scalability: Flexibility and possibility to go from small prototype runs to large-scale production with high manufacturing volumes due to the inherent nature of the technology.

Benefits of Turnkey Assembly

Turnkey PCB assembly offers several benefits and better price, making it a preferred choice for many electronic assembly projects.

- Single Point of Contact: In Turnkey assembly workshop, you contract only one integrated circuit supplier that provides for a PCB production chain: the components source to the final assembly and test. This provides a clear path of communication and facilitates project management on the part of the supplier, making it possible to set up the project without lots of coordination.

- Time Savings: Production line for turnkey assembly goes through much faster compared to the time needed if these processes were managed by separate units. By letting people only tackle the whole procedure from one contractor, the whole assembly process can be sped up and the PCBs can reach the market faster.

- Cost Efficiency: One advantage of turnkey assembly is cost savings when the assembly provider can take advantage of the purchasing power. They may be able to secure wholesale purchases and manage manufacturing practices so that their products are cost-effective. They may pass on the savings to you. Furthermore, a single-source provider streamlines the processes related to multiple vendors, as it saves overhead costs by maintaining only one vendor.

- Expertise and Experience: Service-oriented providers specialize in fully-customizable PCB design, optimized manufacturing, and advanced testing technologies. They can act as a beacon of support when you need professional advice, and this will enable better results for your investment.

- Quality Assurance: Quality control is meant to be applied to each activity in which the production is getting turned into the assembly. The assembly suppliers achieve this by implementing advanced quality assurance protocols and testing procedures with the aim of guaranteeing that the end products are high-performance and operate reliably.

- Scalability: Turnkey assembly services will be scalable as a mode of operation to cater to projects of different sizes and volumes. Assembly providers, no matter if you need only a batch of PCB prototypes or a full-fledged production run, will always try to come up with a suitable amount to meet your requirements.

- Reduced Risk: The accountability of human errors, of which you are the one in charge, reduces greatly with PCB turnkey production. Instability of delays and product quality issues concerning managing multiple contractors also get better as well. The assembly provider supervises the operation from the first step until the end, securing your interests while also creating more risky future roles for you.

- Focus on Core Competencies: Outsourcing print circuit board manufacturing allows you to concentrate your efforts, attention, and resources on those areas where it is harder to build your technological advantage, namely, development and marketing. Moreover, this brings about increased speed for innovation and expansion even while you are doing large bowel movements for the other experts.

Generally, turnkey assembly is considered a user-friendly, efficient, and money-saving method that can be used as a one-stop solution for outsourcing PCB manufacturing, eliminating your supply chain’s delays, decreasing the time to market, and maintaining the quality and durability of your products.

What are the advantages of using full-turnkey PCB assembly services over other turnkey-assembled circuit boards?

Using full-turnkey PCB Assembly offers several advantages compared to other types of turnkey-assembled and printed circuit board assembly, design and boards:

- Simplified Process: With Full Turnkey, you do not have to be involved in procuring the components; you only need to give the design specifications and the manufacturer does the rest, that is PCB manufacturing, assembly, testing, and sometimes packaging and shipment This is the main advantage of it, which makes project management simpler and requires vendors coordination.

- Time Savings: PCB Assembly with Full Turnkey has a higher rate of service delivery than other alternatives, backed up by the manufacturer, who does everything very well. However, in cases where there are strict deadlines for projects or prototypes, the flexibility offered by rapid prototyping is of great use.

- Reduced Risk: By giving a manufacturer the entire production job, you reduce chances of mistakes, delays, and communication failures that result from dealing with more than one supplier. The producer is confident of quality assurance and ensures that the produced PCBs match the specified standards and quality limits.

- Cost-Effectiveness: A full-turnkey service typically leads to cost reduction compared to procuring different components and running separate production processes. By using their medium-scale and wide-spreading networks of suppliers, manufacturers can cut the cost of purchasing components. This eventually reflects on you and the overall price of products. The other point to mention is that it also makes billing payments much more convenient and reduces overhead costs arising from the need to supervise many providers.

- Expertise and Support: Full-turnkey PCB assembly companies with comprehensive capabilities and high knowledge of every aspect of PCB production are now available. They can supply matching conceptual designs, engineering supports, technical advice, and guidance throughout the manufacturing process, thus optimizing your designs by considering manufacturability and performance in mind.

- Scalability: Full turnkey services are particularly known for PCB project to all sizes, from relatively small prototyping to large-scale production. Use our AI to write for you about any topic! Enjoy Manufacturers have the capacity and equipment to mass-produce product in large quantities according to your specifications, guaranteeing uniformly high quality and lack of defects throughout the batches.

The Full Turnkey PCB Assembly service also provides a convenient, efficient and cost-effective alternative to in-house production, thus enabling you to more effectively divert your attention and essential resources to your core competencies.

Partial Turnkey PCB Assembly Services vs Full Turnkey PCB Assembly Services

Turnkey PCB Assembly can be either partial or full and may vary in terms of the level of client participation in the process. Here’s a comparison of the two:

Partial Turnkey PCB Assembly

- In partial turnkey assembly, the client retains some degree of decision-making in the production process.

- Clients normally offer a part of the components and PCB materials to the assembly provider, who in turn undertakes the remaining tasks.

- The customer may demand the delivered parts be of critical nature, proprietary or hard to find.

- The provider of assembly takes advantage of the actions connected with the assembly of the components, testing and control over the quality; however the client may choose to purchase the components, produce the PCBs or perform other operations themselves.

- Partial Turnkey assembly allows for clients who are picky and have specific component preference to join the team that has their own suppliers or maintain the relationships which they already established.

Full-turnkey PCB Assembly

- In full turnkey assembly, the assembling supplier oversees and controls the full production process since beginning to end.

- The customer will provide the technical blueprint and the assembly supplier will handle the processes of component acquisition, PCB manufacturing, assembly, testing and may also do packaging and shipping from time to time.

- Clients have minimal engagement in the manufacturing process, as they can only provide an initial project plan and then check whether the finished product meets their requirements.

- To enhance convenience, all operations are offered on a full-turnkey basis and the client is, therefore, relieved of liability to coordinate with several vendors and monitor the various stages of production.

- In this case, customers may choose to focus on minimalism, time efficiency, and small contribution to the production process.

Conclusion

In conclusion, turnkey PCB assembly encompasses an array of services for outsourcing PCB manufacturing processes, including convenience, efficiency, and quality assurance for clients. Besides, customers can enjoy many advantages, such as a simple communication channel, time efficiency along the process, reduced costs through bulk buying, and access to specialists throughout the sector where the products are produced. Since the entire process would be managed by a single service provider, clients could instead focus on their major tasks and be ensured that their products would be performed well and their time to market would not be a concern. Turnkey PCB assembly complies with a more resourceful strategy, providing a comprehensive all-in-one for small and medium businesses to reduce their supply chain risk and achieve success in the highly competitive electronic assembly market.