In today’s world of the electronics manufacturing industry, turnkey PCB assembly is a key player in the process of taking electronics from the drawing board to the market. This comprehensive guide aims to unravel the intricacies of turnkey PCB assembly, exploring its definition, process, benefits, and applications.

What is Turnkey PCB Assembly?

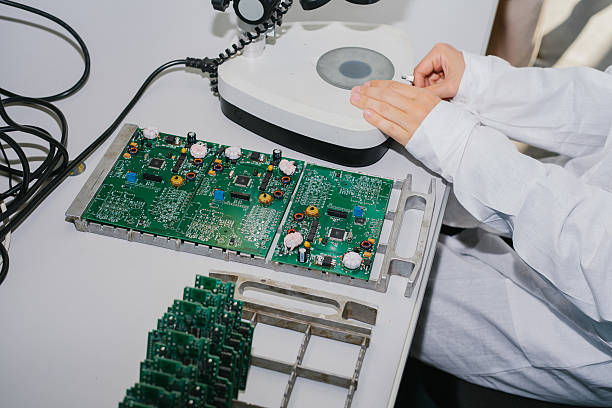

Turnkey PCB assembly means a full-service operation that provides electronic manufacturing services (EMS) through one single-source contract manufacturer. This approach is one in which the manufacturer takes over the whole process of PCB assembly, from a single source of components to the final testing processes and quality controls.

Understanding the expression of “Turnkey” in PCB Assembly

“A “Turnkey” PCB assembly service is one in which the process provider can drive the whole assembly process, starting from the component assembly and finishing with the final product test. Everything from purchasing required components to designing PCB to packing and shipping the parts can all be done on this platform. Basically, customer can only indicate specific services or product specifications that he/she needs. The turnkey manufacturers deals with all the remaining items, among them sourcing for the components and assembly to deliver a ready-to-use integrated product. This approach is beneficial for big and medium businesses that want to streamline their production processes and focus on their core competencies without getting involved in the intricacies of PCB assembly logistics.

Significant Benefits of Turnkey PCB Assembly

- Time and cost savings: Turnkey PCB manufacturing and assembly are done by a single production, and with a turnkey contract, it allows you to save on labor, money, and time and eliminates cross-vendor communication pitfalls.

- Streamlined process: The integratory arrangement of product assembly, on the other hand, offers the possibility for the entire process to be under the surveillance of its own experts, who are in charge of monitoring the PCB assembly solutions of sub-sectional components within their turnkey project.

- Improved design: Companies that specialize in EMS spend more time devoted to improving the highest quality of process design and less time coordinating between fabrication and assembly services.

- In-house communication: Nowadays, a renowned company guarantees on-going interlinked communications within the shop to provide quality satisfaction, decreasing the chances of errors and delays.

- Comprehensive services: Turnkey PCB assembly service involves populating and product prototyping the merged boards at a quick pace, component obsolescence management, as well as aftermarket services.

Key Steps in Turnkey Manufacturing Process

These are the steps:

1. Design Review and DFM Analysis

The procedure starts with an in-depth examination of the customer’s PCB design drawings. Such techniques include the appraisal of project layout specifications, exploration of potential manufacturing issues through Design for Manufacturing (DFM) analysis, and optimization of the design layouts for efficient production.

2. Component Sourcing and Procurement

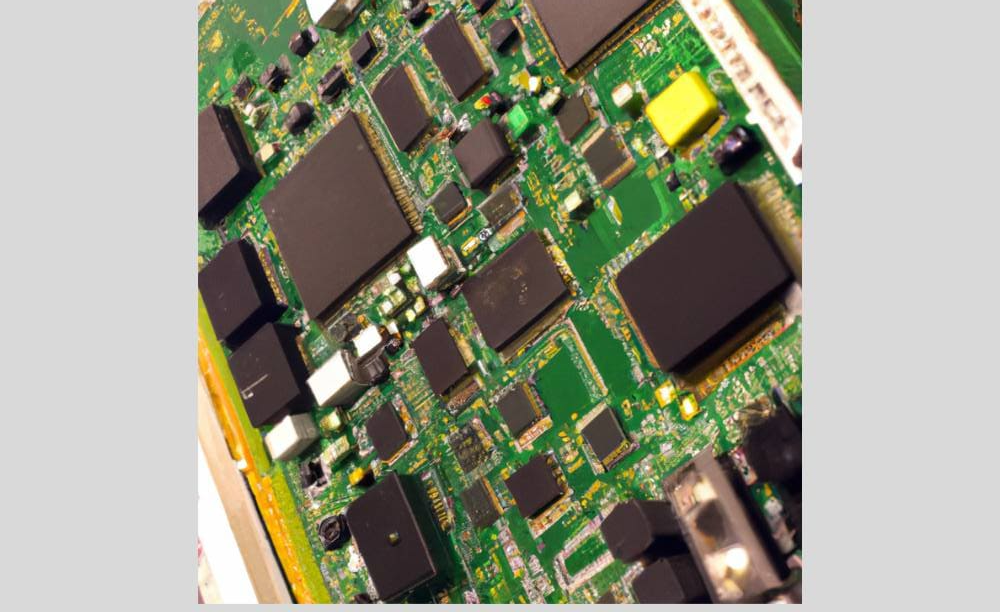

The turnkey manufacturer collects all necessary components with reference to the specifications and product design required. This stands for resistors, capacitors, ICs, all kinds of connectors, etc.

3. PCB Fabrication

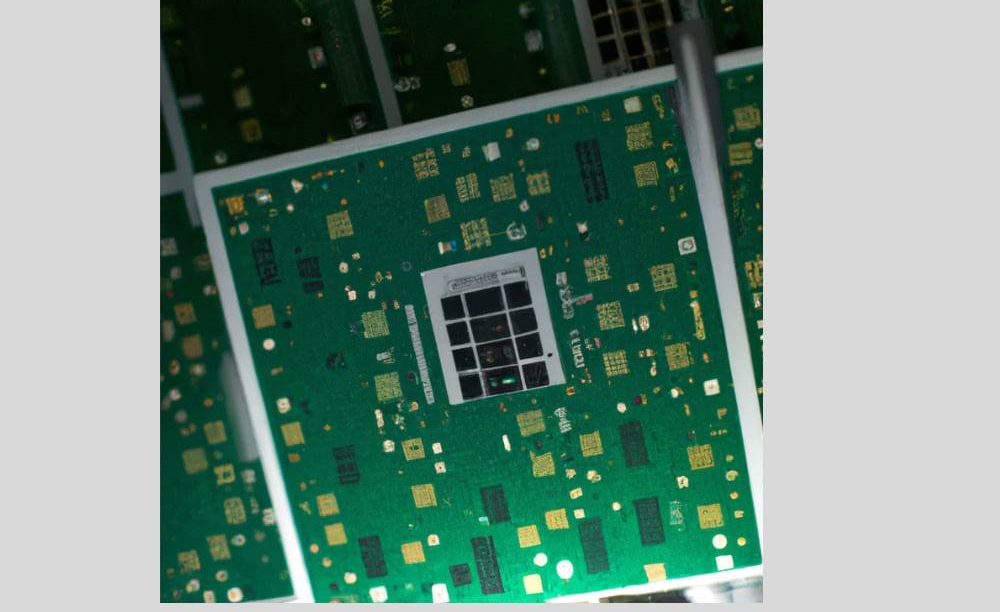

Following that, the next step is sourcing for the components, and the PCB fabrication process starts. The process includes printing the circuit pattern onto the substrate, etching the copper layers, drilling holes, applying the solder mask and the silkscreen, as well as inspecting to make sure that everything fits together neatly.

4. Assembly and Soldering

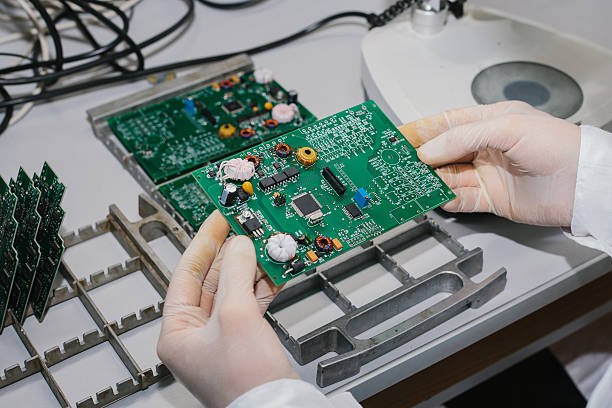

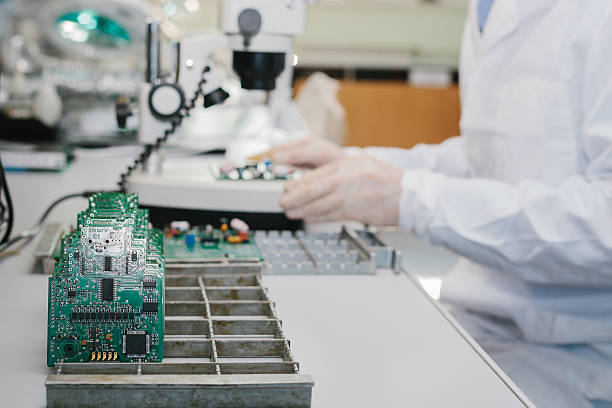

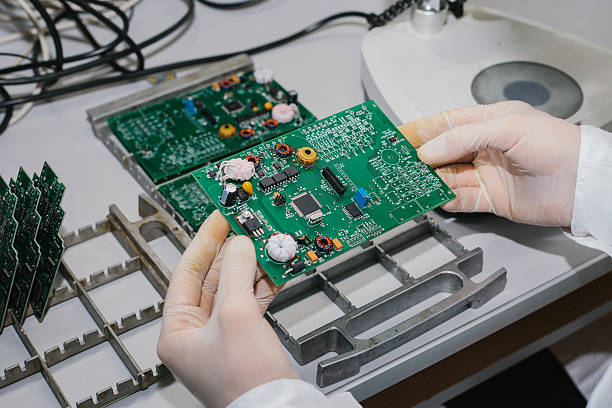

After components are mounted using pick-and-place machines, they are put into the fabricated, assembled circuit boards. Box build assembly is a service not only for the assembly of PCB boards but also for other assembly needs such as tools, cords, and accessories. And some might call this system integration; however, in the last parts of the production, these box build assembly services are complete when the PCB is fully assembled and the final product delivery is set up.

5. Testing and Quality Assurance

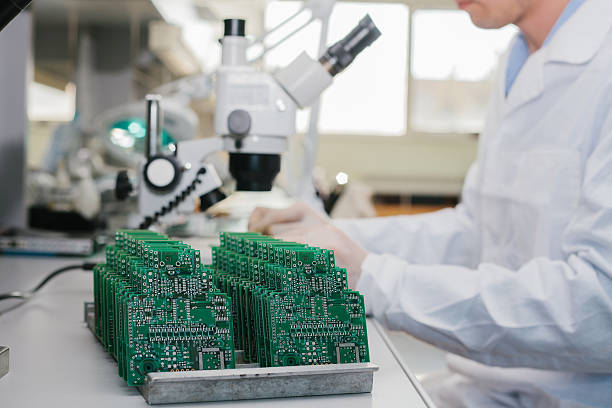

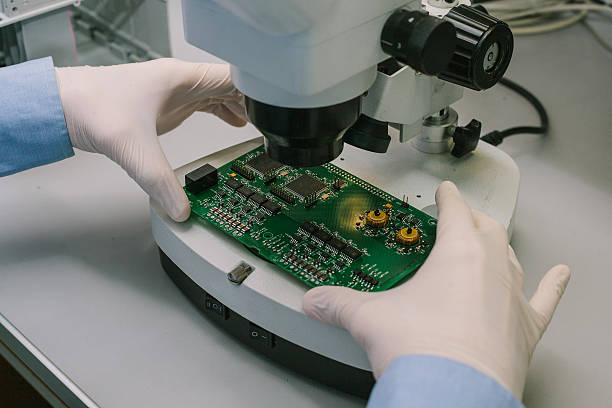

Completed PCB assemblies undergo rigorous testing and quality assurance protocols. This includes functional testing, electrical testing, visual inspection, and adherence to industry standards such as IPC-A-610 for acceptability of electronic assemblies.

6. Final Packaging and Delivery

Once tested and confirmed, the assembled PCBs are then arranged into packages based on the individual customer’s specifications before being distributed to the customer’s designated destination point.

Advantages of Turnkey PCB Manufacturing

These are the advantages of turnkey manufacturing:

Single Point of Contact

One of the primary advantages of a turnkey manufacturer is having a single point of contact throughout the production cycle. It aids the process by letting the parties converse and coordinate their activities, thus forestalling and solving problems promptly, which translates into shorter turnaround times and smoother project execution.

Cost Efficiency

Through the use of this turnkey approach, customers will get a chance to realize cost benefits in bulk purchases, lower their overhead expenditures, and ensure process optimization. It has the ability to compress costs compared to handling one provider at a time and manufacturing in-house.

Expertise and Resources

Turnkey PCB manufacturers often possess extensive expertise, specialized equipment, and established supply chain networks. This allows them to offer high-quality Printed Circuit Boards with efficient assembly processes, comprehensive testing, and adherence to industry standards.

Time Savings

Customers will be able to save major time because, thanks to turn-key manufacturing, they will no longer have to deal with the sourcing of components, managing multiple vendors, logistics, and production-related challenges.

Partial Turnkey vs. Full Turnkey PCB Assembly

In the realm of PCB (Printed Circuit Board) assembly, two common terms often surface: the typology of partial turnkey and fully turnkey. These terms are a comparative concept of production. Awareness that differentiates between partial and full turnkey is very significant to use and avoid project failure in the electronics industry.

Partial Turnkey PCB Assembly

The turnkey PCB assembly has its own part, which the client and the PCB assembly services provide collectively. In this model, the client is required to supply some of the necessary materials and components for this process and the provider takes care of other components such as component buying, printing, assembly, testing, and shipping.

Full-turnkey PCB Assembly

Nonetheless, distinctly in contrast to full turnkey PCB assembly, this procedure allows the representative to proceed with the electronics manufacturing process using a well-defined and passive strategy. In the case of model A, the assembly service provider is responsible, from the supplier of the components to the product ready for delivery to the customers. The clients usually have to deal with specification, design and all project requirements and usually leave everything else to the service providers, who do component sourcing, PCB fabrication, assembly, testing and logistics.

Both partial turnkey and full turnkey PCB assembly are famous methods that are useful in different scenarios. The first step to great result is effective implementation of every ethos and associated project particulars and business objectives.

Turnkey Services Production Process

- Design review: After reviewing the design, the turnkey PCB suppliers make sure its exploration and functionality meet available standards.

- Fabricating bare boards: The manufacturer is responsible for creating the bare PCBs, either in-house or by outsourcing the fabrication.

- Procuring components: Turnkey PCB assembly services handle the sourcing and procurement of necessary components for the assembly process.

- Assembly: The assembler is in charge of framing PCB parts, as their task is to arrange all components with the correct positioning and connection.

- Testing: The catch here, however, is that most of the turnkey PCB assembly houses do offer testing services, which guarantee that the tasked PCBs have met all the rendered specifications and are functioning correctly.

- Component sourcing: The service of assembly does not only help clients’ logistics by offering them ways to manage component obsolescence but also by providing them with alternative sources for difficult-to-find components.

Industries Benefiting from Turnkey Services

In the realm of modern electronics manufacturing, turnkey service is one of the main components of the company’s ability to deliver effective, top-notch, and solid products that can then be used for equipment functioning in multiple industries.

- Consumer electronics is perhaps one of the most prominent sectors benefiting from turnkey PCB services. Manufacturers are compelled to design innovative products under deadline pressure and short product development cycles, so they have to make use of turnkey solutions to minimize their PCB assembly processes. Be it smartphones, tablets, wearables, or smart home appliances,.

- The medical device industry requires PCB solutions that adhere to stringent quality standards and regulatory compliance. Turnkey PCB services bring together the design and manufacturing skills for medical device PCBs to have the highest reliability and precision while taking into consideration regulatory compliance such as ISO 13485.

- Automotive Electronics: In the automotive sector, where reliability and durability are paramount, turnkey PCB services provide robust solutions for electronic components used in vehicles. Turnkey services provide design output ranging from engine control units (ECUs) to infotainment systems and advanced driver-assistance systems (ADAS).

- Aerospace and Defense: Aerospace and defense applications demand PCBs that meet stringent performance criteria and ensure mission-critical reliability. A turnkey PCB service has a specific knowledge base of PCB design and manufacturing, particularly for avionics and defense products, such as avionics, radar equipment, and communications.

Choosing the Right Turnkey PCB Service Provider:

- Consider their years of operation, the complexity of projects they have handled, and their familiarity with the latest technologies and industry standards.

- Measure the capabilities of the provider as well as the types of technologies available. Make sure that they are equipped with the resources, facilities, and experts required to address your particular project demands, such as PCB design, component sourcing, assembly, testing, and packaging.

- Ensure certifications and compliance with set industry standards and regulations are present. Search for certifications such as ISO 9001 for quality management systems, IPC-A-610 for PCB assembly standards, and RoHS (Restriction of Hazardous Substances) compliance for eco-friendly manufacturing processes.

- Demand that the providers give you references or case studies of their successful projects and happy customers.

- Successful cooperation (or partnership) with turnkey PCB service providers requires good communication and collaboration. Evaluate their communication channels, responsiveness to questions, and readiness to work closely with their customers throughout the entire lifecycle of the project.

In Summary

The article provides a detailed overview of turnkey PCB assembly, starting with its definition as a comprehensive service where a manufacturer manages the entire PCB assembly process, including component sourcing, fabrication, assembly, testing, and delivery. It highlights the benefits of turnkey assembly, such as time and cost savings, streamlined processes, improved design, in-house communication, and comprehensive services.

The key steps in the turnkey manufacturing process are outlined, including design review and DFM analysis, component sourcing and procurement, PCB fabrication, assembly and soldering, testing and quality assurance, and final packaging and delivery. The advantages of turnkey PCB manufacturing are emphasized, such as having a single point of contact, cost efficiency, expertise and resources, and time savings.

This article also explains the difference between partial turnkey and full turnkey PCB assembly, where partial turnkey involves collaboration between the client and the assembly provider, while full turnkey offers a hands-off approach with the assembly provider managing the entire production process. Industries benefiting from turnkey services are discussed, including consumer electronics, medical devices, automotive electronics, aerospace, and defense, with considerations provided for choosing the right turnkey PCB service provider.