Find out that advanced PCB solutions, from flexible and rigid-flex routing to high-frequency and metal-core PCBs, are bookshelf inventions that range from boosted functionality to reduced size and, hence, better performance. Reveal the newest developments in modern PCB technology behind the progress in consumer electronics, automotive systems, medical devices, and even in a broader range of interconnected devices. We will then envision a foreseeable future.

What is a printed circuit board?

A PCB or printed circuit board, is a flat board layer made of non-conductive material (usually fiberglass-reinforced epoxy) upon which traces and paths of metals are engraved to act as a basic platform to mount and connect electronic components. The plot it displays is a thin layer of metallic foil or pieces which are coated by copper and composed of several traces whose function is to join the parts of the transistor. The bumps thus provide an avenue for the electrical signals and power to move between the different components, with the aim of running the circuitry as per the designer’s intentions. PCBs remain prevalent in electrical manufacturing despite their reliability, lack of space, and automatic assembly of jobs. They animate any electronic devices, whether it is simple smartphones or complex medical devices and automotive systems.

Different Types of Circuit Board & Their Applications

Printed Circuit Boards (PCBs) become fundamental components in modern electronics as they function as the base and structure that inside devices keep all the electronic components connected to each other. They are provided different types of pcbs, such as categories that cater for specific uses and necessities. From simple single- or multi-layer boards to the application of complex multi-layer configurations, PCBs are an effective method of distilling what functions, performance, and form factor an electronic product is going to look like.

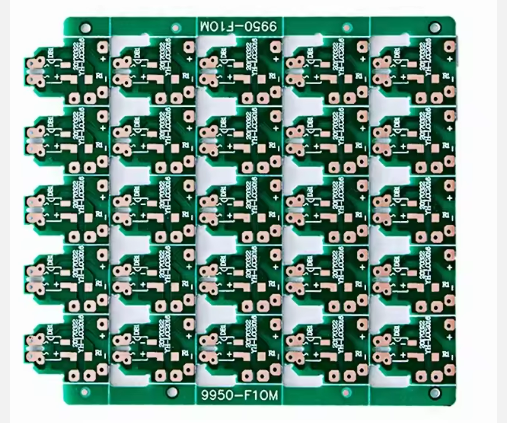

Single-Layer PCBs

These are primitive types flex circuits that have just one layer of the material used as a substrate (usually a composite of epoxy and fiberglass) and the conductive layer on one of multiple layers on its sides (usually that copper layer).

- Advantages:

- Such products were easy to produce and required only a small amount of initial capital.

- Developed widely to be operated for simple electronic circuits with few parts.

- The ultimate convenience of the viewing is because of its simple layout and single-path structure.

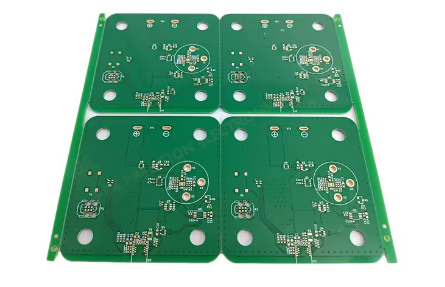

Double-Layer PCBs

Termed as 2-sided PCBs, they have conductive material on both sides of the top substrate layer: copper layers connected by plated through-holes (vias). Consumers notice them in portable devices, such as mobile phones or tablets.

- Advantages:

- Has more tracks of routing compared to single-layer PCBs.

- It is applicable to simple circuits where components are placed on the same side of the board.

- Allows for a better level of EMI shielding compared to single-layer PCBs.

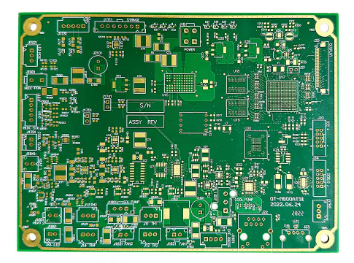

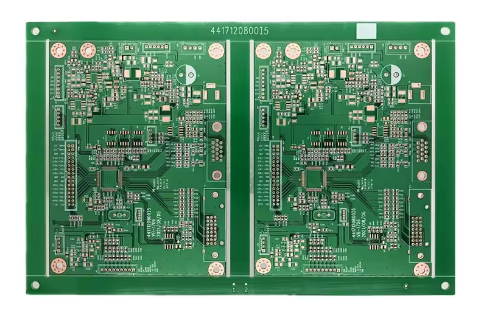

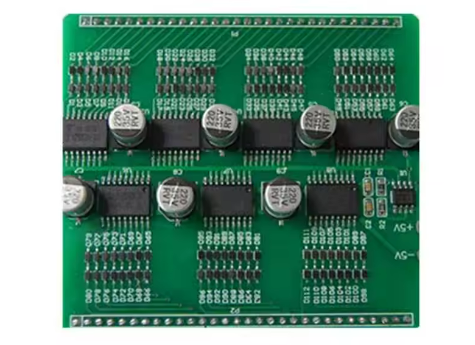

Multi-Layer PCBs

These boards include over 2 layers of substrate material, which are stuck on each other by conductive layers sandwiched in between them. Akin to multi-layer PCB boards, they provide higher density and are generally used in several electronic devices with high complexity, such as computers, smartphones, and medical devices.

- Advantages

- Enables component integration and systematic engineering of sophisticated circuitry.

- Offered signal integrity and inhibiting electromagnetic interference are both better.

- It is possible to make the industrial designs smaller form and weight, as well as lighter.

- The system essentially means that heat transfer is optimized.

Rigid PCBs

These boards are more widely utilized, having a full surface mount with rigid pcb and non-flexing substrate materials made of epoxy or fiberglass. They are widely employed in applications where reliability and fastidiousness of surface mounting are required.

- Advantages

- Comes with the facility of having good structural strength and durability.

- Suitable for an application where devices consist of fixed components.

- It ensures the even flow and force of electricity over time.

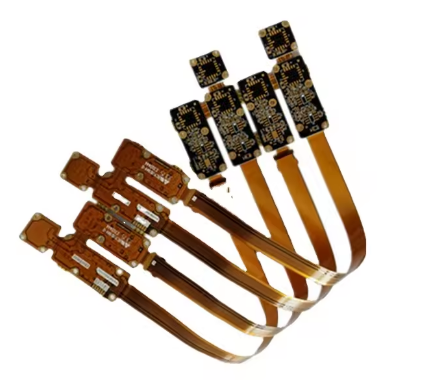

Flex PCBs (Flexible Boards)

New PCBs being developed are made of flexible substrate materials such as polyimide. That allows them to be bent or twisted without breaking. They can be useful to keep things in the same place or to use in motion instead of heavy and large objects, for example in wearable devices, automotive electronics, etc.

- Advantages

- Provides an opportunity to have bendings and folds within structures, hence allowing their use in shortened and limited facilities.

- reduces the number of connectors and cables, which in turn boosts reliability.

- Allows for designs that are bending or shaping.

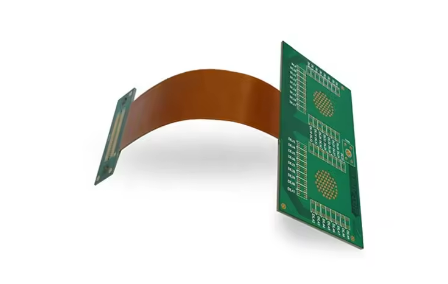

Rigid-Flex PCBs

These boards have the best features of both rigid boards and flexible PCBs, including a lot of dimensions, shapes, and surface profiles. These rigid flex boards are planed in shapes where a product needs to be both flexible and strong to make it strong and flexible and they are seen in aerospace and medical products.

- Advantages

- Enables the use of advantages both of rigid and flexible PCBs.

- Enables complex three-dimensional configurations.

- Ensures single-wire connection and does not require assembly steps, rather improving reliability and reducing assembly time.

High-Frequency PCBs

This type of PCB is created to function at higher frequencies and is utilized in domains like telecommunication, radar systems, and satellite communication.

- Advantages

- Specially designed to avoid or limit significant signal loss or distortion even with high-frequency signals.

- Suitable for telecommunications, radars and fast data processing facilities.

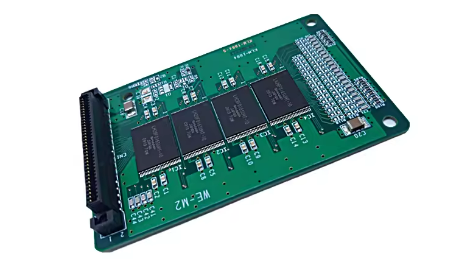

High-Density Interconnect (HDI) PCBs

HDI PCBs feature high wiring densities along with fine features which permit freighter designs to become more compact and lighter in weight. They are widely used in smartphones, tablets and other portable gadgets, which include newly emerging portable devices

- Advantages

- It gives an opportunity for a higher wire density and more precise, minute details accurate replication.

- It makes even a smaller and lighter design possible.

- Improves signal quality so that it is very reliable and reduces electromagnetic interference.

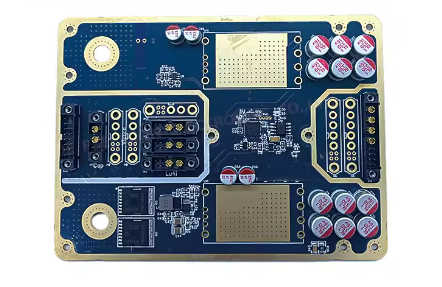

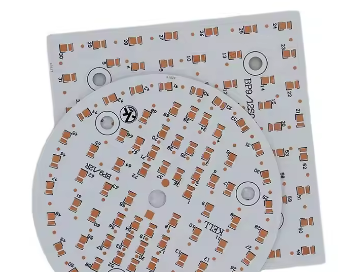

Metal Core PCBs (MCPCBs)

These boards are made from a material of core, usually aluminum or a copper foil, instead insulating material of rigid substrate of the conventional one: fiberglass substrate. MCPCBs ease the task of heat dissipation and are employed in high-power LED lighting supplies and automotive electrics.

- Advantages

- Excellent thermal conductivity is allowed by them, allowing them to do high-power things.

- Provide better reliability and a longer lifespan due to lower operating temperatures. The crisis in global confidence has led to an era of economic uncertainty and weakness.

Aluminum-backed PCBs

These boards are also equipped with similar aluminium backing layers to help with heat dissipation. These metal oxides are widely used in applications where dispersing heat is a major enabling factor, such as in LED lighting and power electronics.

- Advantages

- Superior heat conduction and heat removal are among the many advantages.

- Appropriate for use in components that need thermal management, like LED lighting and power electronics.

TYPES OF PCB APPLICATIONS

PCBs are employed in many types of other electrical components and devices operating in the fields of computers, office automation, medical equipment manufacturing, protective solder masks, and so on. Here are some common types of PCB applications:

- Consumer Electronics:

- Smartphones

- Tablets

- Laptops

- Televisions

- Gaming consoles

- Wearables (integrated in smartwatches, fitness monitors, etc.)

- It necessitates home appliances (microwaves, washing machines, fridges.)

- Industrial Electronics:

- Control systems

- Automation equipment

- Robotics

- Test and measurement instruments

- Industrial sensors

- Power supplies

- Automotive Electronics:

- Engine control units (ECUs)

- Infotainment systems

- Advanced driver-assistance systems (ADAS)

- On-board diagnostics (OBD)

- Light system (LED headlamps and tail lamps)

- Control EV powertrain

- Communications:

- Telecommunication infrastructure implements subsequent networking tools (routers, switches, and base stations).

- A combination of several products, including modems, routers, and access points, among others, serves as an umbrella term for wireless communication.

- Satellite communication systems

- Antenna arrays

- Medical Electronics:

- Non-invasive equipment such as MRI, CT (A), and ultrasound are the medical imaging modalities.

- Patient monitoring systems

- Life-support systems

- Diagnostic devices

- Implantable medical devices

- Aerospace and Defense:

- Avionics

- Radar systems

- Communication systems

- Guidance and navigation systems

- Missile systems

- Surveillance equipment

- Energy and Power Electronics:

- Renewable energy sources, such as solar inverters and wind turbines.

- Power distribution systems

- Battery management systems (BMS)

- Smart grid technology

- Power converters and inverters

- LED Lighting:

- Street lighting

- Commercial lighting fixtures

- Automotive lighting

- Indoor and outdoor displays

- Signage and backlighting applications

- Security Systems:

- Surveillance cameras

- Access control systems

- Alarm systems

- Biometric identification systems

- Fire and safety systems

- IoT (Internet of Things):

- Smart home devices and appliances (thermostats, door locks, and security cameras) can be automated to improve convenience and efficiency.

- Industrial sensor networks and devices (IoT) can be effectively powered by wireless, as the technology has become the most commonly used form of communication.

- Wearable health monitoring devices

- Environmental monitoring systems

- Smart agriculture solutions

These digital devices underline the fact that PCBs can be found almost everywhere, where they operate as a critical component for electronic devices, ensuring that their seamless operation.

Considerations in Choosing the Ideal Types of PCBs in your Project

The selection of the perfect PCB may be the most critical element in your project since it is responsible for many aspects like performance, reliability, and cost-efficiency. Here are key considerations to keep in mind:

Functionality and Complexity

Evaluate the complexity of your circuit as well as their functions and tasks. Choose a kind instead of a PCB which will fulfill the amount of electric components required, the signal integrity expectations, and the ease of the routing.

Space Constraints

Assess required space inside the product enclosure for your solution. In the case of confined spaces, using flexible or rigid-flex PCBs to follow the original shaped lines or to achieve space compactness is recommended.

Environmental Conditions

Analyze the environmental conditions your PCB will be exposed to, like temperature swings, moistness, vibration, or shock. Identify the type of PCB which has such characteristics as weather-resistant material and solid construction for enduring external environmental challenges.

Reliability Requirements

Think over the reliability requirements, especially for those with critical applications or where the environment is supposed to be harsh. Pick a type of green PCB which is most well-known for its robustness, reliability, and durable operation.

Signal Integrity and EMI/EMC

Analyze the integrity of signals and electromagnetic compatibility (EMI/EMC) for your own circuit boards by considering the following:. PCBs that are high-frequency or PCBs with controlled impedance may be required to decrease the signal loss since it does get interfered.

Thermal Management

Figuring out the thermal management needs of your PCB and checking if your application generates a lot of heat are crucial steps in ensuring that your system operates reliably over time. If we cannot solve the heat problem, metal-core PCBs or designs with thermal expansion capabilities may be used to ensure the dissipation of heat.

Cost Considerations

Place performance expectations on equal footing with budget considerations. Various PCB types are characterized by the complexity of the manufacturing processes, material arrangements, and assembly approaches, that consequently can change project costs.

Manufacturability and Assembly

Give some thought to those parameters which characterize the procedure of the manufacturing and assembly of your scheme. Pick a PCB form factor that is adaptable to the set of assembly processes and manufacturing qualifications.

Future Scalability and Upgradability

Expect modifications to the product already launched or new product releases. Decide on a circuit board fabrication and type which would be easily adaptable and would be able to overcome any challenges and grow with the company’s changes.

Regulatory Compliance

Verify that the PCB type you select meets the market standards, for example, RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Through a careful analysis of these considerations and a proper verification with your project necessities, you will be in a position to get a good idea of what PCB is perfect for your application.

Conclusion

In summary, though, the wide range of circuit board types provides many alternatives designed to satisfy dissimilar needs and occasions within the electronics industry. Single-sided PCBs can tackle the concept because of their simplicity and cheapness, although they cannot respond to the demands of space and complexity in advanced electronics. In terms of routing options, PCBs with two sides are an available extension, which makes them perfectly suitable for moderately complex designs and ensures affordability.

In critical or manifold applications, however, multilayer PCBs show up as the chosen board that provides high fidelity, shielding, better signal integrity, high-speed circuits, and low interference. Although their higher cost and the need for complex construction are obstacles, their ability to create very fast and efficient electronics is a benefit in this regard for the sake of high-end devices.

Stiff PCBs deliver stability and durability, typical of conventional situations, whereas flexible PCBs have the flexibility required in mobile devices with limited space. Rigid-flex PCBs unite both the worlds of rigid and flexible by taking from both the qualities of structural strength and flexibility and, at the same time, resulting in a more expensive price.

Working with high-frequency PCBs, these can be tailored to meet the needs of different types of pcbs and circuits handling high-speed signals, and metal-core PCBs help to eliminate highly localized heat dissipation, which is relevant for communication systems and high-power electronics. While the bare board manufacturers are proud of their effectiveness, they still face some specific production problems with this type of microchip, and this costs the system of boards.

To pick the right kind of circuit board for the product, the things to consider while purchasing are the cost of the product, the performance requirement, the condition of the environment, and the manufacturing process capabilities. Every one of them has a kind of trade-off between feature, complexity, and cost that should be considered very carefully, and one has to offer a compelling argument for the most appropriate solution before any judgment can be made.

Therefore, the evolution and diversity of circuit board types speak for the drive towards innovation and complexity in electronic design and assure the top-notch quality of electronic systems in every industry.

FAQs

The following are some of the commonly asked questions about the many different types of electronic and printed circuit boards available, ranging from the cheap and easy-to-use models to the complex and high-speed ones.