ALUMINUM PCB

What are Aluminum PCBs?

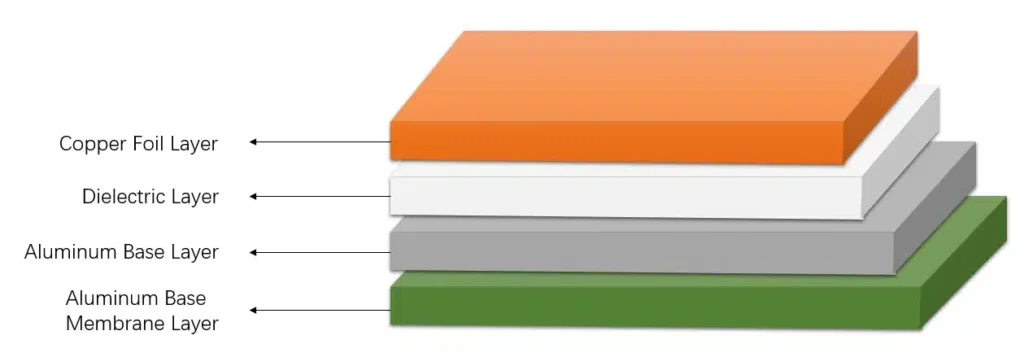

Aluminum PCBs, often referred to as Metal Core PCBs or Insulated Metal Substrates, feature a metal core, typically aluminum, to enhance heat dissipation. These boards are essential for managing the thermal challenges in high-power applications like LED lighting, automotive electronics, and power converters. Aluminum PCBs are comprised of a four-layer structure that includes copper foil, a dielectric layer, an aluminum base, and an aluminum base membrane.Aluminum PCBs improve component performance and longevity by efficiently dispersing heat, making them a superior choice for designs requiring excellent thermal management.

Advantages of Aluminum PCBs

Environmental Sustainability: Aluminum PCBs stand out for their eco-friendliness. Aluminum, being both recyclable and non-toxic, aligns with green manufacturing practices, promoting energy conservation throughout its lifecycle from production to assembly, thereby contributing significantly to environmental protection efforts.

Enhanced Heat Dissipation: Aluminum’s superior thermal conductivity efficiently removes heat from critical components, safeguarding them against damage due to overheating. This feature is essential in maintaining the performance and longevity of high-power electronics by minimizing thermal stress.

Durability and Reliability: Offering remarkable strength and durability, aluminum PCBs reduce the risk of damage during manufacturing, handling, and daily use compared to traditional materials like ceramic or fiberglass. This robustness ensures a longer lifespan for devices, enhancing their overall reliability.

Lightweight Design: Despite their enhanced durability, aluminum PCBs maintain a lightweight profile, adding structural integrity without the added bulk. This quality is particularly advantageous in applications where weight reduction is crucial, such as in aerospace and portable electronics.

Cost-Effectiveness: The abundance of aluminum makes it a cost-efficient choice for PCB manufacturing. Its ease of mining and processing leads to lower production costs, making aluminum PCBs a financially viable option for a wide range of applications, from LED lighting to automotive systems.

ALUMINUM PCB APPLICATIONS

The widespread use of Aluminum PCBs is attributed to their exceptional heat resistance and dissipation capabilities. Below are the primary applications of Aluminum PCBs:

LED Lighting: Aluminum PCBs are prominently utilized in LED applications, such as traffic signals, automotive lighting systems, and general lighting solutions, leveraging their exceptional heat dissipation properties.

Power Supply Units: Serving a critical role in DV/AC converters, switching regulators, and similar power supply mechanisms, aluminum PCBs excel in maintaining operational efficiency through superior thermal management.

Audio Equipment: Amplifiers, preamplifiers, and power amplifiers benefit from aluminum PCBs, which facilitate enhanced performance and thermal stability in audio systems.

Communication Devices: Essential for high-frequency amplifiers and filtering circuits, aluminum PCBs ensure reliable performance in communication electronic equipment by effectively dispersing heat.

Automotive Applications: Aluminum PCBs are integral to automotive electronics, contributing to the functionality and safety of dashboards, tail light assemblies, and other systems through robust thermal control.

Consumer Electronics: Utilized in computers, office automation, and various household gadgets, aluminum PCBs offer durability and efficient heat management, supporting the prolonged use and reliability of consumer devices.

Basic structure of aluminum PCB

Aluminum PCBs are distinguished by their unique four-layered architecture, incorporating a metal base for enhanced heat dissipation, coupled with electrical insulation properties, tailored for applications requiring efficient thermal management.

Copper Foil Layer

Serving as the circuitry’s foundation, this layer utilizes a copper foil, thickness ranging from 1oz to 10oz, to form the electrical pathways. Its substantial current-carrying capacity is pivotal for the PCB’s functionality.

Dielectric Layer

Positioned between the copper foil and the aluminum base, this layer is a thermally conductive barrier that also electrically isolates the board’s layers. With thicknesses between 50μm to 200μm, it is essential for mitigating thermal and mechanical stress while ensuring efficient heat transfer.

Aluminum Base Layer

The cornerstone of the PCB, this aluminum alloy substrate underpins the entire structure, offering unmatched thermal conductivity. It plays a critical role in heat dissipation, thereby maintaining the PCB’s performance under high thermal loads.

Aluminum Base Membrane Layer

This protective layer shields the aluminum substrate from physical and chemical damage. Available in two variants for standard and high-temperature applications, it ensures the base layer’s integrity against etching and abrasions, contributing to the PCB’s durability.

Performance of Aluminum PCB

Thermal Dissipation Efficiency: Aluminum PCBs excel in thermal management compared to traditional FR4 PCBs. With a thermal resistance range from 1°C/W to 2°C/W for aluminum versus 20°C/W to 22°C/W for FR4, aluminum PCBs ensure rapid heat dispersion, significantly enhancing component safety and stability.

Superior Thermal Expansion Control: The coefficient of thermal expansion for aluminum closely aligns with copper, enabling aluminum PCBs to minimize the issues of thermal expansion and contraction. This feature guarantees the longevity and reliability of both the surface-mounted components and the overall device.

Dimensional Stability: Aluminum PCBs demonstrate exceptional dimensional stability. When subjected to temperature variations from 30°C up to 140°C or 150°C, they exhibit minimal size change, only about 2.5% to 3.0%, ensuring consistent performance under varying conditions.

Additional Advantages: Aside from their remarkable thermal properties, aluminum PCBs contribute to improved power device SMT compatibility, circuit design thermal expansion mitigation, and overall product life extension. They reduce product volume, cut down on hardware and assembly costs, and offer a durable alternative to ceramic bases, with enhanced insulating and mechanical properties.

Types of Aluminum PCB

According to the application type and material of the dielectric layer, aluminum PCB mainly has the following types:

Through-Hole Aluminum PCB

This variant incorporates a pre-drilled aluminum layer with thermal bonding materials on both sides, facilitating multi-layered construction for enhanced thermal management and robust circuit integration.

Flexible Aluminum PCB

Innovative for its adaptability, this type combines polyimide resin with ceramic fillers to offer unprecedented flexibility, thermal efficiency, and insulation, allowing for versatile shaping without the need for connectors or cables.

Multilayer Aluminum PCB

Designed for complex electronic needs, these PCBs layer multiple thermally conductive dielectrics, accommodating dense circuit designs and high power applications with efficient heat dissipation capabilities, suitable for advanced telecommunications, aerospace, and computing.

Hybrid Aluminum PCB

Merging aluminum with FR4 materials, this type offers a balance between mechanical support and superior heat dissipation, making it ideal for RF applications where both thermal management and structural integrity are critical.

High-Frequency Aluminum PCB

Tailored for high-speed applications, it features materials like polyolefin or polyimide resin to enhance PCB flexibility, minimizing signal loss in RF communication systems, radar setups, and high-speed digital devices.

Aluminum PCB manufacturing difficulties and solutions

As an advanced PCB, Aluminum PCB’s manufacturing process still has its own particularities, and it will encounter many challenges during production. The following are the difficulties in the Aluminum PCB manufacturing process and their solutions.

Copper Foil Etching Challenges: Aluminum PCBs, utilized in high-power devices, employ thick copper foil, necessitating precise trace width compensation for etching. Accurate design adjustments and meticulous control of etching parameters are essential to maintain trace width and spacing within design tolerances.

Solder Mask Printing Complications: The substantial copper foil thickness poses challenges for solder mask printing, leading to potential discrepancies between the trace surface and the board. Implementing high-quality solder mask oil, adopting dual printing techniques, and possibly prefacing solder mask application with resin filling are critical for achieving quality results.

Mechanical Manufacturing Hurdles: The mechanical processes like drilling, milling, and molding in aluminum PCB production can leave burrs, affecting electrical strength. Utilizing electric milling and professional milling tools for precision and adjusting drilling parameters to avoid burrs are pivotal for maintaining manufacturing quality.

Our manufacturing capabilities

CAMTECH Circuit has extensive experience in aluminum PCB manufacturing and is committed to providing you with high-quality aluminum PCBs. Here are some of the features and services we provide.

Specifications

Aluminum PCB Capabilities

Layer

1-6 Layers

Build Time

1 -4 Weeks

Aluminum PCB Types

Single-sided, Double-sided, Multilayer

Quality Level

IPC-A-600 Class 3/2

Thermal Conductivity

1W/mK to 9W/mK

Aluminum PCB Substrate Material

Pure aluminum, Al-Mg alloy, Al-Mg-Si alloy, pure aluminum

Dielectric Layer Material

Polymer Filled With Ceramic

Copper Thickness

1OZ to 8OZ (35μm to 280μm)

Manufacturing Condition

Full-line operation; Production Machines And Equipment Specialized For Aluminum PCBs

Surface Finish

ENIG, OSP, HASL, Immersion Silver, Immersion Gold