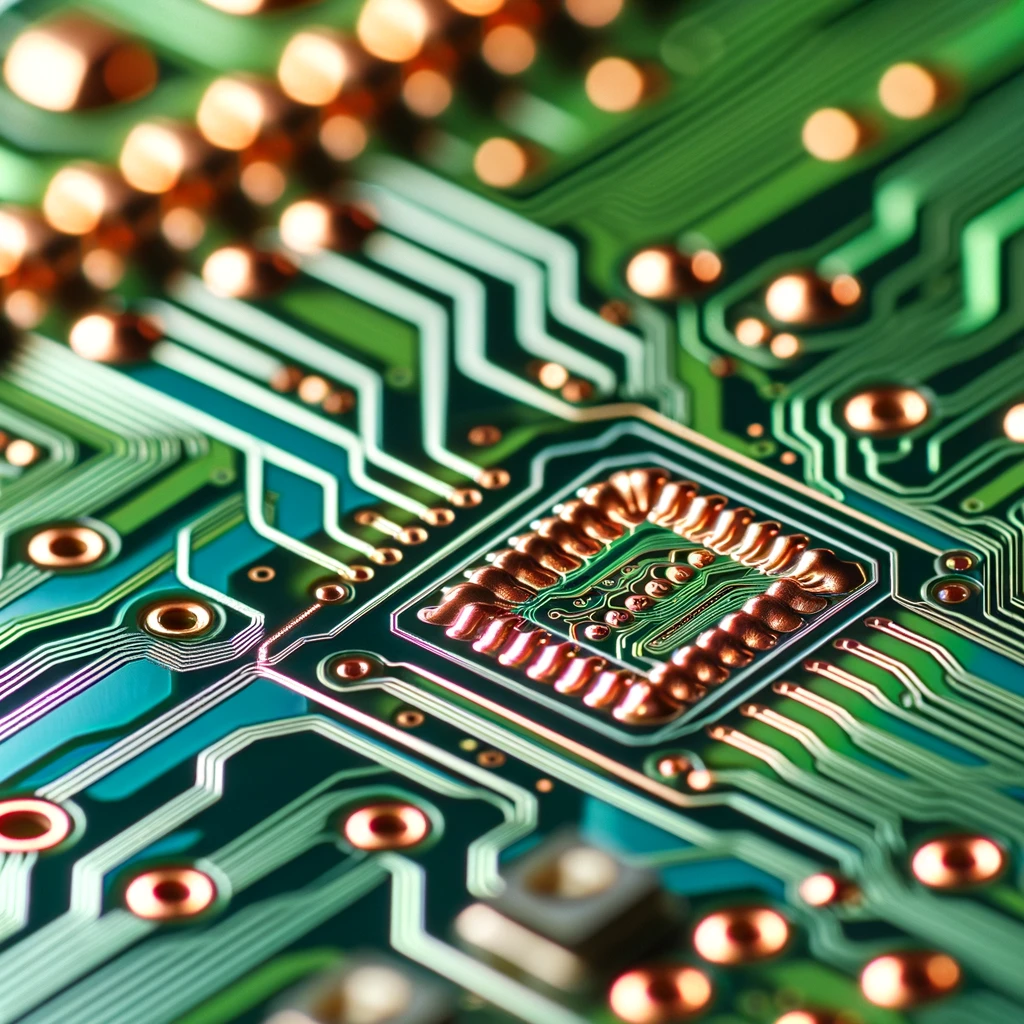

Printed Circuit Boards (PCBs) are responsible for the majority of electronics, from the bells in our city streets to the electric engines of spacecraft. These detailed printed circuits boards are an amazing achievement in modern engineering field and consist of interwoven layers with conductive foil and insulating substrates where working components in computers, phones, and educational devices are now placed. Complexity resides within the VIA connections, which are of basic importance because they assist in the transmission of electrical signals from one PCB layer to another. In this article, we will explore the universe of via sizes, discover why they are crucial and evolve on the verge of the standards through which optimal connections are made.

Understanding the Importance of VIA Sizes

VIA network that is formed by the IP connections is essential to circuit production, with VIA vessels copper pads being an indispensable part of the production process. The sizes of such via holes and pads have pivotal influences on several features of PCB, such as signal integrity, thermal management, manufacturing feasibility, and so on. Our decision on the appropriate VIA dimensions remains absolutely vital to providing dependable electrical contacts and furthering the circuit´s performance.

The Basics of VIA Sizing

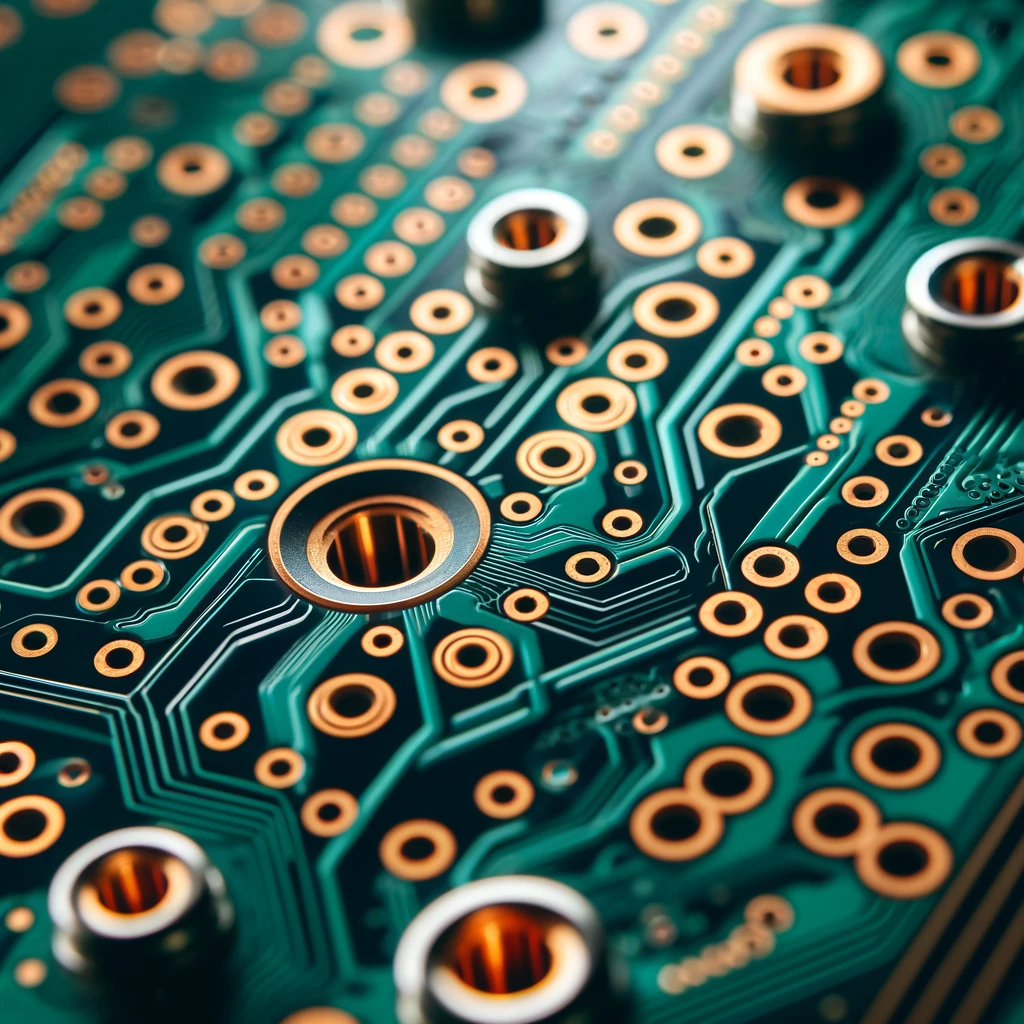

VIA sizing typically refers to two key dimensions: VIA hole deification depends on the VIA hole defecation and the VIA pad defecation’s VIA hole size determines how large the hole will be drilled through the PCB substrate, whereas the VIA pad diameter (maximum lead diameter) determines how large through hole parts the surrounding conductor will be plated and vary from 0.2 to 0.5mm gap width and fit accordingly the size of the pads based on this diameter Electrical and mechanical properties of the VIA connection are multifaceted. This encompassing property is both attributed to the inventions of electrical and mechanical structure of the VIA.

PCB design standardization is relevant, as it has features aimed at both easing the manufacture process and assuring product interchangeability of various systems. These are just some of the VIA classifications stated as industry standards measured by thickness of the PCB, copper weight, the evaluation of manufacturing capabilities, and similar considerations. Typical VIA sizes vary from 0.2 to 0.5mm gap width and fit accordingly the size of the pads based on this diameter.

Factors Influencing VIA Size Selection

When selecting VIA sizes for a PCB design, several factors must be taken into consideration:

- Signal Integrity: Signal transfer integrity can be affected by variant aspect size through impedance and signal loss. Sufficient size for VIA allows maximum signal signal quality protection and signal purity during signal transmission.

- Thermal Management: With the larger VIA, the size of the component that is vulnerable to getting overheated can be used. This will improve the overall heat dissipation function of the device and make it ideal for high-power applications. Proper VIA sizing is one of the determinants of effectiveness of thermal performance, which will eventually result in mitigation of temperature-related problems.

- Manufacturability: The VIA sizes must have the process lines in making the PCB. Standardization of VIA sizes being chosen guarantees that production passes without defects and assures obtaining the final results.

- Cost Considerations: Aggravating the fact, VIA sizes differ in the efficiency of their signals as well as the thermal management; the latter may increase the manufacturing cost with extra materials and manufacturing. Since choosing UAV sizes involves balancing the requirements of performance and cost factors, it is indispensable.

Pcb drill sizes and type of pcb via also minimum hole size

PCB drill sizes differ with respect to the diameter of the laser drilling hole, as the circuit design and manufacturing process entail. The drill size you choose determines the measured drilled hole size, which is important for precise interconnections within the different layers of the PCB.

Drill sizes are most common between 0.1 mm and 6.0 mm or even more, for the smaller, standard drill sizes being standard practice in creating intricate circuit patterns with close components and smaller traces. The choice of drill size depends on some parameters, such as how complex your pattern is, how thick your PCB substrate is, and how dense you need VIA connections to be.

Types of PCB VIAs:

There are types of vias such as;

Through-Hole VIAs

Through Via-in-the-hole distance (TH-VIA): barrel-like conductors extend completely through the board’s substrate, joining traces on stacked layers. VIAs or vertical interconnects, are normally employed in conventional PCBs and have been known to provide tough conductive pathways and mechanical stability.

Blind VIAs

The Blind vias form an outer layer to one or more of the inner layers or inner layers to outer layers without going through the complete substrate of the PCB. The VIAs are a drilled conductivity path from the external surface of the PCB that ends inside of the substrate at a various level c given board thickness. The most simple kinds of Blind VIAs are utilized primarily in order to cut down the amount of needed surface on multilayer circuit boards and also enable high-density route routing.

Buried VIAs

Buried VIAs: The internal layers of the PCB will effectively hide VIA in the form of completely buried Vertical Interconnect accesses, and this will not result in any extensions of VIA to the external surface of the PCB. They cross over tracts on various inner tracks lines, thereby not interfering with the outer layer routing. With Vias running through the substrate, problems related to the complicated multilayer model, signal interference and degradation of signal integrity can be avoided.

STANDARD VIA SIZES ACCORDING TO THE BOARD ASPECT RATIO

Conventional VIA sizes are defined relative to the specifications of the circuit board width and the smallest pilot and drill hole. It is through the ratio of the PCB thickness and the diameter of the pilot hole drill holes that sizes shall be derived. This affirms manufacturability and reliability capability in a PCB layout.

Via Type vs. Via Size

While via type deals with the role of avenues within the PCB design, via size pertains to the kind of avenues used. With the help of via, refers to a set of vias in the specific connection configuration and target and this is another way to connect different levels of interconnection to the tungsten carbide drill bits. And now the size, which characterizes the size of hole or finished hole size and its impedance as compared to those parameters like signal, quality, thermal management, and manufacturability, which impact the process of manufacturing of the whole circuitry,. While the size of the pin determines its placement and electrical connection path within the PCB layers, the via size, another key feature in PCB design, controls the electrical and mechanical properties of the PCB, which both need to be considered in PCB layout and manufacture.

Standard Via Sizes to Avoid Assembly Problems

Standard VIA sizes are defined already for any designer to ward off issues related to assembly during PCB production. These standard sizes are being adhered to by designers to avoid risks such as solder bridging, insufficient solder joint strength and poor component placement difficulties PCB assembly process will be much simpler to achieve varied standards of VIA sizes (standard pcb drill sizes) and higher manufacturability levels and as a result, improved PCB quality can be achieved the copper pad.

PCB Standard Via Sizes and Pad Size Basics

Understanding PCB standard VIA hole sizes and pad sizes is fundamental to successful circuit board design. VIA sizes refer to the diameter of the drilled holes connecting different layers of the PCB, while pad sizes indicate the diameter of the conductive pads surrounding these holes.

Choosing appropriate VIA and pad sizes is crucial for several reasons:

- Electrical Performance: VIA and pad sizes influence signal integrity and impedance matching across the PCB. Proper sizing ensures reliable electrical connections and minimal signal distortion.

- Thermal Management: Larger VIA sizes and pads facilitate better heat dissipation, essential for components prone to overheating or high-power applications.

- Manufacturability: Standard VIA and pad sizes streamline the fabrication allowance process, reducing the risk of manufacturing defects and ensuring compatibility with industry standards and equipment.

Common PCB standard VIA sizes range from 0.2mm to 0.5mm, with corresponding pad sizes to accommodate these larger holes used. However, specific applications and design requirements may necessitate variations within this range.

In summary, understanding the basics of PCB standard VIA sizes and pad sizes is essential for designing reliable and manufacturable circuit boards. Careful consideration of these dimensions ensures optimal electrical performance, thermal management, and manufacturability in PCB designs.

Best Practices for VIA Size Selection

To ensure optimal VIA size selection, consider the following best practices:

- Consult Industry Standards: Apply the guidelines, which in this case are the industries standards are stipulated for recommended VIA sizes in effect with your particular case and design requirements.

- Collaborate with Manufacturers: Work hand in hand with production houses so as to be cognizant of the flexibility or efficiency of different VIA sizes and production mechanisms.

- Use Simulation Tools: Make use of simulation interfaces in order to carry out analysis over the electric and thermal efficiency of various via designs and find out the optimum design accordingly.

- Prototype and Test: Build your microcontroller board design and do meticulous test to find out a certain VIA dimension, confirming that they do perform as expected

Conclusion

In the delicate world of PCB design, via sizes play a central role in ensuring the links between all elements are sound and the performance of the circuit is at its best possible level. Sizing VIA plays a pivotal role in the design of PCBs and comprehending that can lead to a functional and effective circuit. Moreover, getting acquainted with standard VIA sizes and choosing an appropriate one can increase the quality, reliability and performance of a PCB board. Whether working on electronic and electrical components, for consumer devices or sophisticated industrial systems, the proper size of Via is crucial to secure the circuits and to assure the electronic apps are a success also this is the recommended pcb drill sizes.

Though the devil is in the details, endeavor to interpret the importance of via sizes in ensuring your PCB designs work to their maximum capability and efficiency to the pcb drill size.